The Context

For decades now, HVAC systems have been retrieving and analyzing sensor data to run systems more efficiently and provide more comfortable environments. However, recent developments in IoT technologies are enabling new capabilities that are making waves in the HVAC market. A big player in the commercial HVAC segment wanted to vault ahead of the competition by creating a system that supports internet monitoring, predictive maintenance, total controllability, remote diagnostics and system adaptation, paving the way for minimal labour requirements and low-cost environment control. Tismo was entrusted with the development of the scalable architecture for the IoT system

The Challenge

We had our task cut out for us. On the face of it, a web application was to be developed to configure, control and monitor a large number of IoT devices. These devices would have unique IDs and would send data at regular intervals. So it follows that a server had to be architected, with the capability to handle a large number of devices. Additionally, the application was to be hosted on cloud services without any dependencies. Pretty straightforward so far right?

Navigating the Pitfalls

However, our team knew better than to jump ahead without mapping the potential pitfalls. With large number of devices sending data at the same time, data loss was likely to occur. Also, high-end server resources would be required to collect all this data at the same time and in the long run, that would affect the client’s bottom line. In a traditional architectural approach using RDBMS, complex data parsing and filtering algorithms would be necessary. Moreover, complex visualization code would have to be written based on the data.

Slow system and application response were red flags waiting to pop up. And integrating any data analytics or machine learning tool in the future would be a challenge in itself. Besides all this, scalability issues were likely to pop up and we wouldn’t be in this business if we were going to let our clients bear the brunt of this.

The Future proof Solution

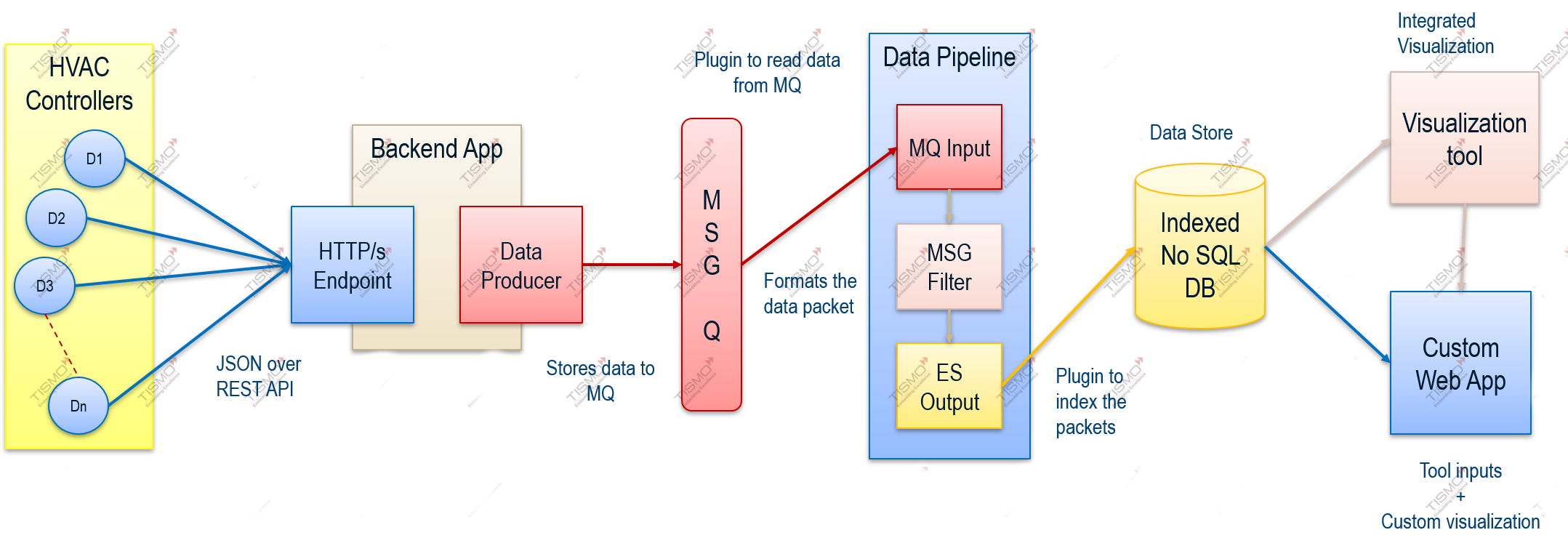

The Tismo team came up with a scalable architecture, focussing on easier data gathering and processing with zero data loss. The thought process was to use message queues that would collect the high speed incoming data and enable response or further processing one after the other. We employed a time series database and developed a workflow where parsing and categorizing data would be easier without implementing complex data parsers. Another decisive decision was to implement easier data pipelines with capability to stream to multiple devices.

Architecture for HVAC system

The architecture ensures that future modifications do not pose a challenge and the databases can be easily connected to services for any data analytics, machine learning needs. Using databases that could perform queries at lightning speed over huge amount of data and scalable by design, Tismo was able to implement an architecture and develop a web app that could seamlessly support upto 100K IoT enabled HVAC devices.

The Highlights

- Message Queue to collect the high speed incoming data and enable response or further processing while ensuring optimal functioning.

- Data Pipeline to automate the process of extracting data from various sources, after defining what, where and how data is to be collected, transformed and loaded.

- Indexed No SQL DB to ensure the performance, scalability and flexibility needs demanded by this next-generation, data-intensive application.

The Impact

Tismo delivered a secure platform and protocol agnostic scalable architecture, based on open-source technologies, that could leverage data from a variety of sensor types to give the best possible picture of the HVAC system’s function. This is a stark contrast to traditional IoT solutions, built for single use cases. The use-driven functionality allows faster reaction times and optimises power consumption.