The Context

Flue gas analysis is an important part of minimizing the environmental impact of process heaters, steam boilers and thermal oxidizers. It is deployed to monitor industrial emissions in a wide range of applications including cement and lime, hydrocarbon processing, metals and mining, pharmaceutical, and power and steam generation. A leader in industrial gas analysis was looking to introduce a new online flue gas analyzer into the market. Having extensively worked with gas analyzers, Tismo was tasked with the development of a software to configure, calibrate and run diagnostics on the online flue gas analyzer.

The Problem

The online flue gas analyzer is crucial to process control and safety in combustion applications. The instrument was being designed to accurately measure oxygen (O2), combustibles (CO + H2) and methane (CH4). It would ensure safe, reliable operation of the combustion chamber, through continuous diagnostic checks and alarms. The software being developed by Tismo would have to offer a complete solution for field-servicing of the online flue gas analyzer. It would have to assess the health of the online flue gas analyzer and periodically validate the combustion measurements.

The Solution

Tismo developed a software to configure, calibrate and run diagnostics on the online flue gas analyzer. It was developed using C# and WPF on the .NET framework and employed the MVVM architecture. The application communicated with the instrument sensors through Modbus RTU protocol on an RS-485 interface. It was developed for the Windows operating system and was designed to be installed without the need for administrator access.

The software enabled the configuration and calibration of oxygen (O2), combustibles (CO + H2) and methane (CH4) sensors. Users could select ports and enter sensor address to connect the sensors to the selected ports. Options to configure analog output, process alarms, date, time, sensor name, process pressure etc. were available to the users. The software also allowed users to monitor gas flow, on time, instrument temperature, cell temperature and cell voltage. The software also supported a debugger screen for data transmission and offered an option to restore factory settings.

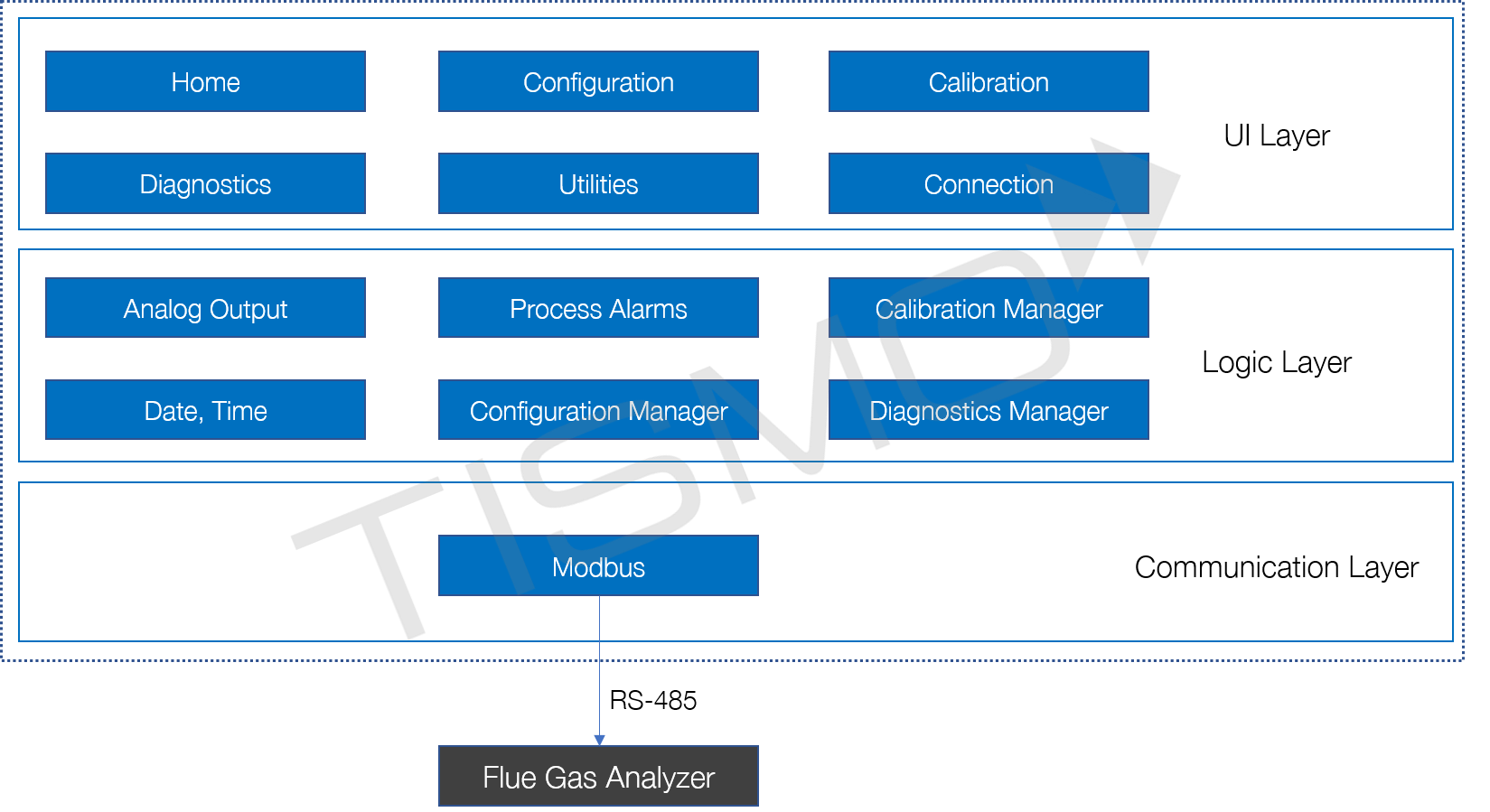

Architecture Diagram of the Online Flue Gas Analyzer Software

The architecture of the software comprised a User Interface (UI) layer, a Logic layer and a Communication layer. The UI layer was responsible for the graphical representation of data on the desktop software tool. The Logic layer was responsible for orchestrating the communication between the UI layer and the instrument sensors. The communication layer was developed as a thin wrapper layer, responsible for communication with the online flue gas analyzer over Modbus RTU protocol on RS-485 interface.

Tismo developed a simulator that replicated the functioning of the online flue gas analyzer, as part of the test setup. Gas flow conditions, boundary values, sensor output ranges, communication ports, alarm conditions etc were simulated. Test scenarios were created and exhaustively tested. The entire project was executed based on the project plan and the requirements document created by the Tismo team, in concurrence with the client’s engineering team. SCRUM methodology was used for the project management. During the course of the development, the Tismo team organized weekly sprint meetings with the client to provide regular updates on progress. Each release of the project was accompanied by a release note, detailing the features, user instructions, installation setup, test specifications and 3rd party tools. Test reports were also handed over to the client, detailing the pass/fail status of each test case. The team also maintained a comprehensive design document, that captured the details of the development and feature implementation at each stage of the project.

Summary

Tismo developed a software for field-servicing of an online flue gas analyzer. It could be used to configure, calibrate and run diagnostics on the instrument and was developed using WPF and C#/.NET. Users could configure and calibrate sensors and run diagnosis on the instrument. Tismo developed a simulator that replicated the functioning of the online flue gas analyzer. Test scenarios were created and exhaustively tested. Tismo has extensive experience with the design and development of analytical instruments. Our strong technical team, backed up by experienced project managers and our sound domain knowledge enables us to deliver high quality products to customers across the world.