The Context

Vitamins are vital for energy production and metabolism in the human body. According to a report by Acumen Research and Consulting, the global Vitamin Ingredients Market is forecasted to be worth around USD 5.1 billion by 2026. A leader in the analytical instruments space wanted to develop a state-of-the-art Vitamin Analyzer for quantitative and qualitative analysis of vitamins in food samples. Tismo was brought on board to undertake the electronics design, firmware and software development of the instrument.

The Problem

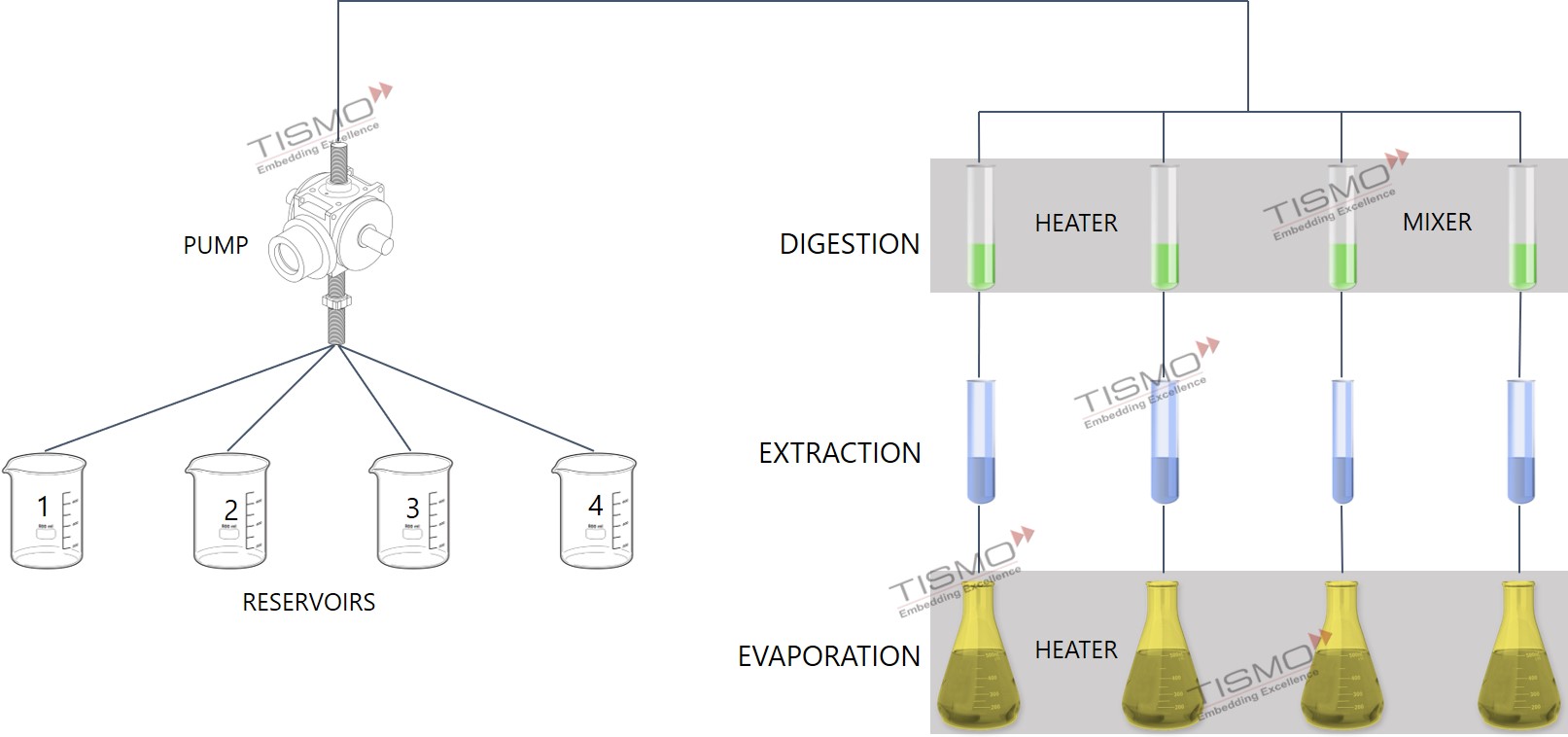

The Vitamin Analyzer would have to study Vitamin and Total Fat content in a food sample. This would have to be realized by replicating the metabolic processes in the human body. The instrument would have to simulate the processes of digestion, extraction and evaporation. The temperature, pressure and movement of food particles within the human body would also have to be replicated. The instrument would also have to support hassle-free software and firmware updates and a modern, intuitive User Interface (UI).

Workflow diagram of Vitamin Analyzer

The Solution

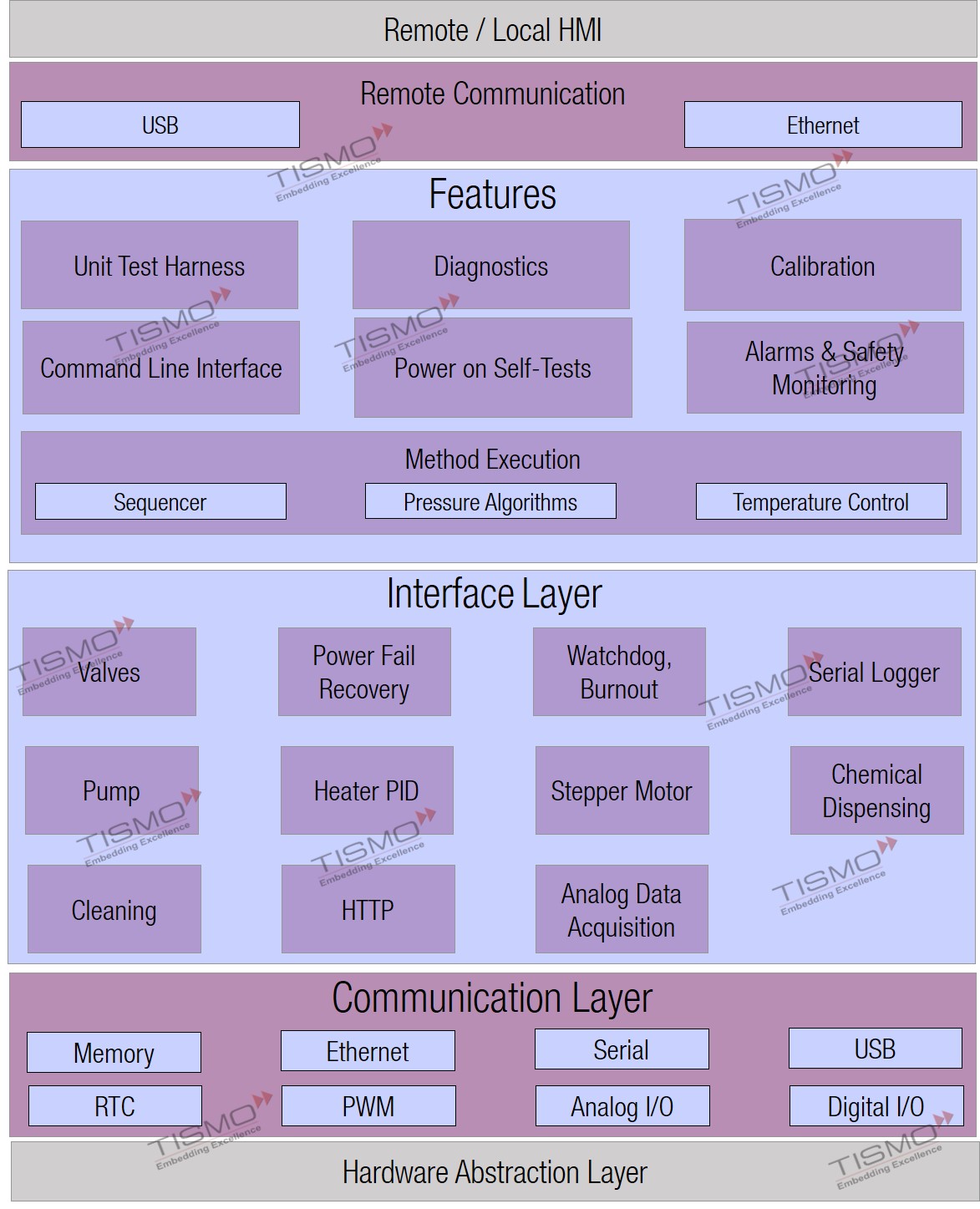

Tismo carried out the electronics design, firmware and software development of the Vitamin Analyzer. The instrument was designed to emulate digestion, extraction and evaporation. This was achieved through an array of sensors, heaters, valves and motors. Tismo followed a dual process architecture for the electronics design. An STM 32 ARM Cortex M4 was used for the real time control of the instrument. Supervisory control and the web based Human Machine Interface (HMI) was supported by an Intel Industrial PC

The controller board firmware was developed using Embedded C and C++, with JSON files being used for data exchange. The firmware developed by Tismo supported up to 200 customizable methods, real time monitoring, calibration and diagnostics of temperature sensors and solenoid valves. It also provided real time control over the pumps, mixers, heaters and blowers used by the Vitamin Analyzer. The heater was programmed to maintain the temperature at 0.5 degree Celsius accuracy.

Firmware Architecture of Vitamin Analyzer

Tismo implemented a modern, intuitive UI via Web HMI on Intel Industrial PC running a Linux operating system. A Kestrel web server was implemented on the Industrial PC to host the Web HMI. The UI was developed using HTML, CSS and Typescript on the Angular framework. Web animations were used to deliver an enhanced user experience. C# on ASP.NET Core framework was used for the instrument logic. The software supported creation and editing of methods, real-time monitoring of analysis, calibration, data logging, fault detection and diagnostics. Additionally, firmware and software updates could be carried out via USB mass storage. The Web HMI also enabled remote access to the instrument over HTTP protocol. The communication to the firmware of the instrument was through serial communication via USB.

Summary

Tismo carried out the electronics design, firmware and software development of a Vitamin Analyzer. The instrument simulated the processes of digestion, extraction and evaporation. The temperature, pressure and movement of food particles within the human body were also replicated. A dual process architecture was followed for the electronics design, with an STM 32 ARM Cortex M4 being used for the real time control of the instrument and an Intel Industrial PC being used for supervisory control and the web HMI. The controller board firmware was developed using Embedded C and C++. A modern, intuitive UI was implemented via Web HMI and was developed using HTML, CSS and Typescript on the Angular framework. C# on ASP.NET Core framework was used for the instrument logic.