The Context

Semiconductor manufacturing is a multibillion-dollar business and semiconductor wafer processing is it’s heart and soul. An Equipment Front End Module (EFEM) is the mainstay of semiconductor automation, shuffling silicon wafers between ultra-clean storage carriers and a variety of processing, measurement and testing systems. The robotics and peripheral equipment used in the semiconductor wafer processing environment work with unbelievable precision and speed.

A market leader in advanced Wafer Handling and Transfer systems wanted Tismo to develop an EFEM control software for it’s latest generation of EFEMs. It had to support various aspects such EFEM Configuration, Sequence Programming, Maintenance & Troubleshooting, Diagnostics features etc. Additionally, the software was to be highly customizable and able to change the sequence configuration based on the customer configurations and processing requirements.

The Challenge

An EFEM control software has to control a combination of one or more Load ports, Aligners, Buffer module, Robots etc. Also, the software that runs on the EFEM should handle all possible combinations of the devices without having to make changes to the software. In a nutshell, the challenge before Tismo was to create a highly modular software that could handle every permutation of the possible device configurations and operational sequences and provide the agility of customization, without the need for any additional programming.

Pitfalls

Due to the lack of pre-integrated components, most existing EFEM control software have very limited productivity. The existing designs are stitched together with complex and costly custom software and this affects flexibility and re-use and tend to be error-prone. Tismo engineering team understood that since there were no similar products that encompassed the diverse requirements, achieving world-class throughput, capabilities, maintainability and reliability would be a peak hard to scale. Moreover, abiding by the development schedules would require a lot of planning and effort from the part of the project manager.

The Solution

The Tismo team developed a unique and powerful configurable software environment for EFEM control. The foremost benefit to the OEM is that the solution eliminates the need to develop new and time-consuming software for each customer or for different configurations of an EFEM. The high-performance wafer handling sequences can be created as a flowchart using drag-and-drop of device specific operations. Integration is fast and robust. Wafer handler maintenance is eased, reliability improved, and downtime reduced. The software was built using C# on .NET framework and other standard components. The user interface was developed using WPF.

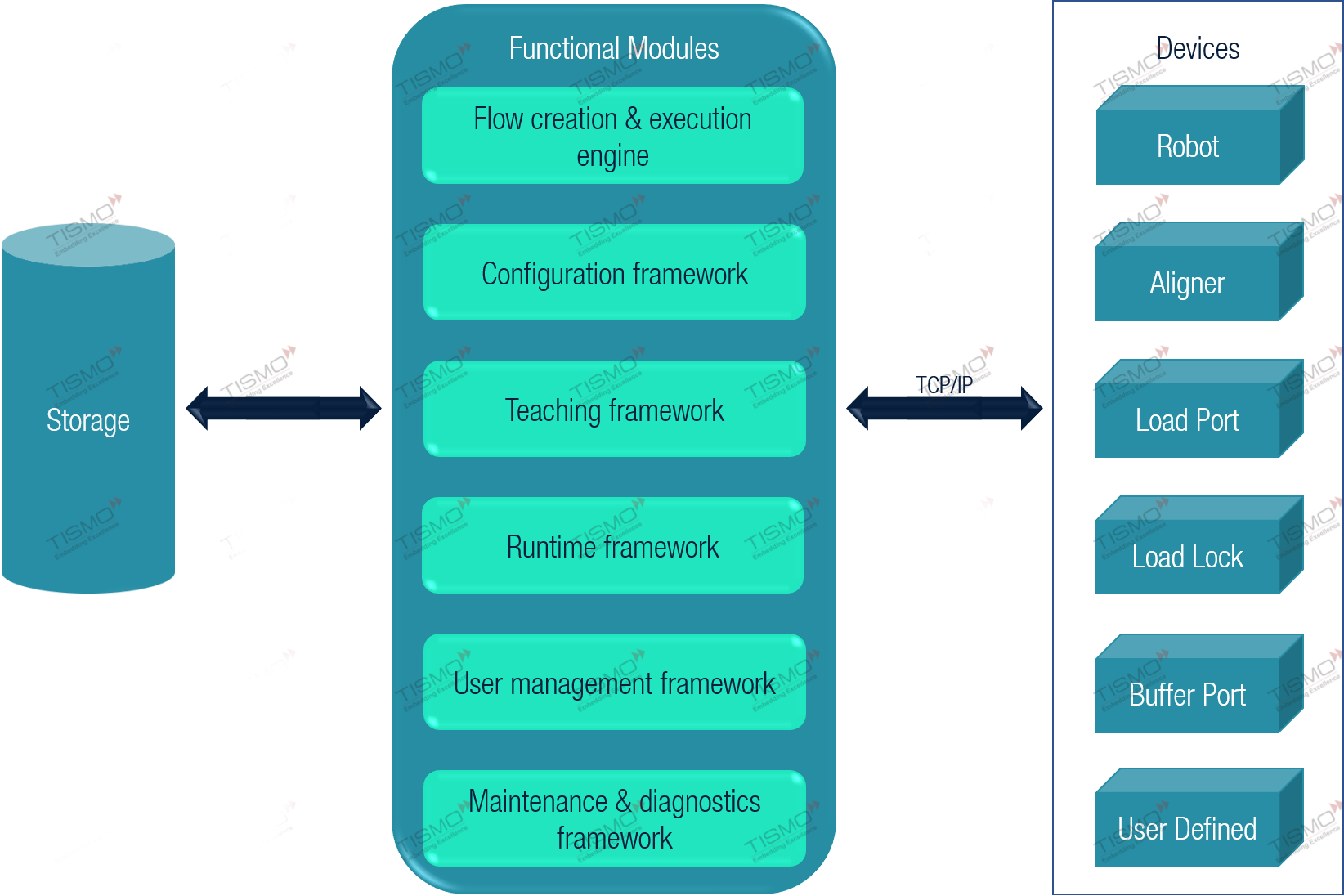

Software Architecture of EFEM for Semiconductor Wafer Processing

Tools to set up, maintain, operate, and debug individual robots were also developed and integrated into the software. Tismo’s software solution enabled the OEM to build process tools and featured a flexible, modular architecture based on industry standards to enable fast set-up, reduced cycle times, and seamless integration with existing fab equipment and processes. The high configurability and a wide selection of off-the-shelf options made it readily adaptable to meet application-specific needs and keep pace with rapidly evolving industry requirements. The Tismo team was able to implement memory optimization, reducing the previous 1.5 GB memory requirement to 180 MB. To top it off, the Tismo engineers were able to add functionality to integrate any one of the client’s device with a third-party wafer handling environment.

Cover Image: “Wide shot to show the entire silicon wafer” by Rob Bulmahn is licensed under CC BY 2.0